Health & Safety

Audit & Monitoring

Corrective and preventive actions are undertaken in a timely manner and monitored to ensure they are effective and efficient to ensure continuous improvement.

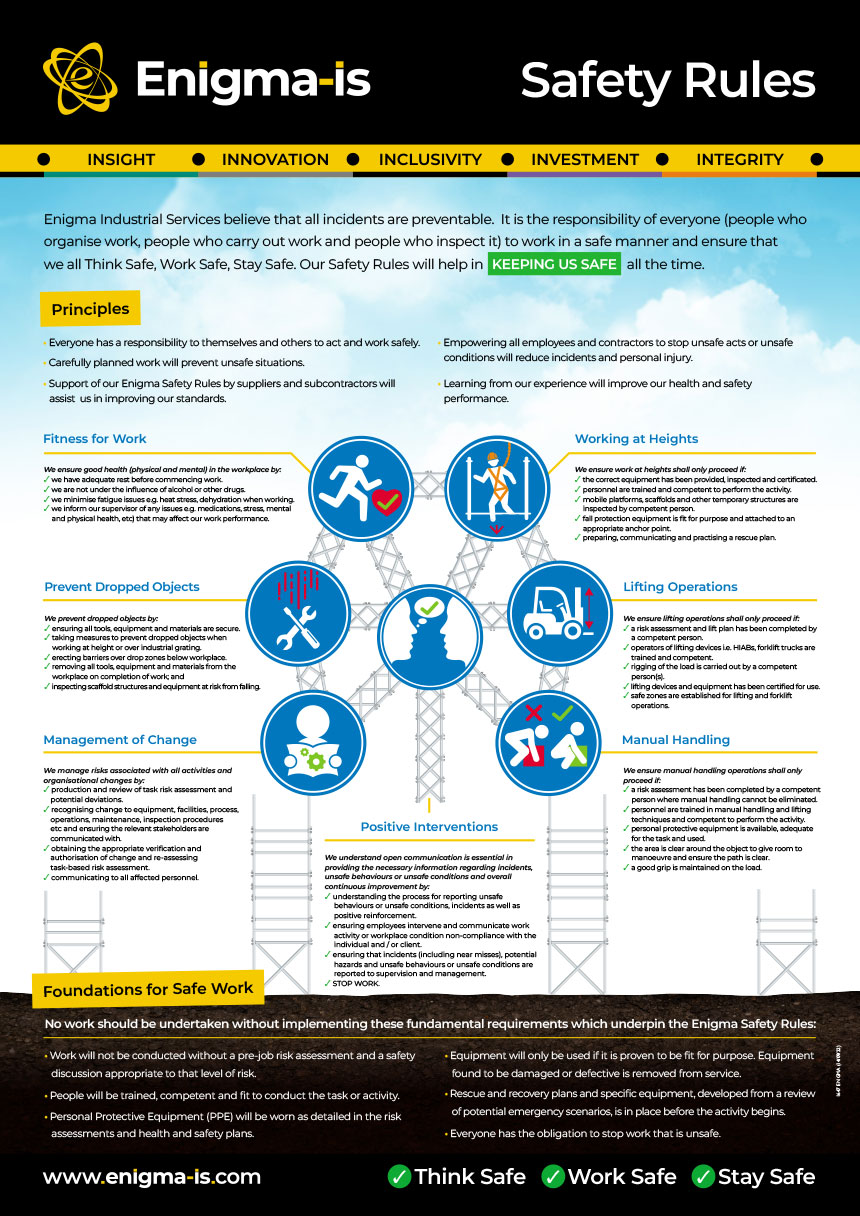

Enigma Safety Rules

Enigma Safety Rules will help in KEEPING US SAFE

- Fitness for Work - ensure good health (physical and mental) in the workplace.

- Working at Heights – ensure correct equipment has been provided, inspected and certificated.

- Prevent Dropped Objects – ensure all tools and equipment are secure.

- Lifting Operations - risk assessment and lift plan has been completed.

- Management of Change – ensure change is communicated to all affected personnel.

- Manual Handling – ensure personnel are trained in manual handling and lifting techniques.

- Positive Interventions - ensuring employees intervene and communicate work activity or workplace condition non-compliance.

Communication, Consultation and Participation

Effective communication is a fundamental tool for a successful Business Management System (BMS) and involves:

- Meetings – a range of meetings from senior management to the workforce.

- Campaigns – including bulletins, alerts, toolbox talks, presentations, workshops.

- Training – including bespoke trade skills training, health, safety, environment and Sustainabilities.

- Audit & monitoring – joint site inspections involving senior management and the workforce to identify areas for improvement.

- Information - including bespoke location / site inductions, notice boards.

- Trade participation – including representation on external organisations committees for example the National Access & Scaffolding Confederation (NASC) and Engineering Construction Industry Association (ECIA).

Risk Management

Statutory compliance is managed using Legislation Update Service (LUS) Compliance Management which provides Health, Safety & Environment legal, risk and opportunities and target & objectives registers. The LUS cloud-based system is monitored monthly, updated incorporated and communicated to the company as appropriate.

Enigma risk and incident management are recorded on Sevron365. Risk assessments and method statements are produced in collaboration with the client and workforce as appropriate to ensure any site-specific arrangements are addressed and assist Enigma Industrial Services to assess the significant risks, identify suitable control measures and develop safe systems of work for the workforce to follow, minimising the potential of injury and ensuring compliance.

Skills Training

Enigma Industrial Services Ltd is an accredited training provider of the Construction Industry Scaffolding Record Scheme (CISRS) and International Powered Access Federation (IPAF). Enigma is committed to providing skills training to enable employees fulfil their role responsibilities effectively, efficiently whilst improving their knowledge, skills and ability which is an investment in the future.

Enigma Industrial Services Ltd deliver training courses designed for all levels of personnel from apprenticeships for those just starting out in their career through to courses for yard personnel, scaffolders and inspectors. In addition to inhouse training, employees may undertake additional training identified through training needs analysis for example First Aid, Confined Space, CATC Asbestos Awareness for Scaffolders, NVQs in Health & Safety Practice.

Energy Management

Enigma Industrial Services Ltd, is certified to ISO50001:2018 Energy Management System (EnMS). Monitoring and collecting and analysing monthly energy measurement data from locations, we develop data reports and bulletins enabling the effective management of energy resources, identifying reduction in consumption and expenditure and improvements where possible. Energy bulletins also include ‘home’ improvements which could reduce our employee’s consumption and expenditure.