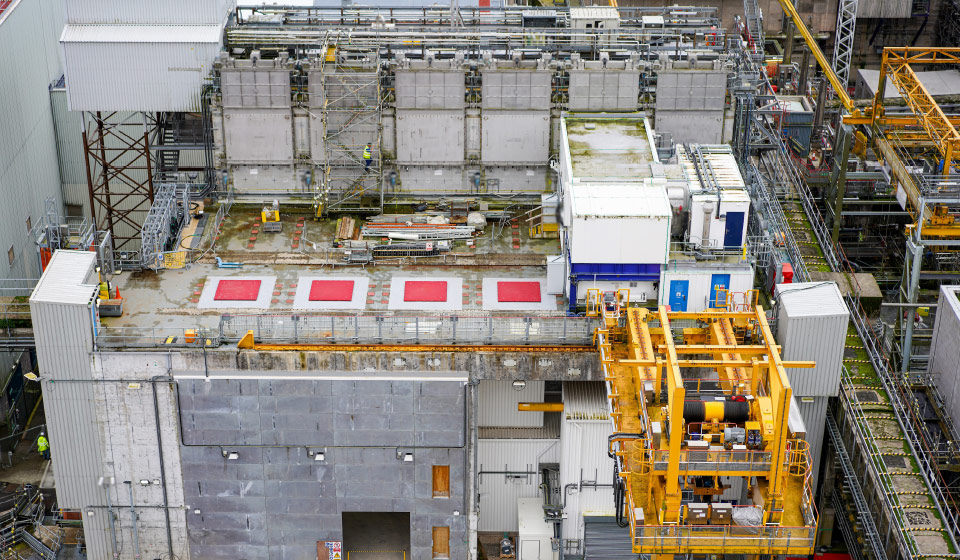

Pile Fuel Cladding Silo (PFCS) Project

Navigating Complexity with Precision at Sellafield

Having established ourselves as an integral part of Sellafield’s high-hazard risk reduction programme strategy, Enigma continues to provide exceptional temporary works support on a range of complex projects across the Sellafield estate.

In 2015, Enigma was selected by Bechtel Cavendish Nuclear Solutions to support the Pile Fuel Cladding Silo (PFCS) project, deemed one of the most complex and difficult decommissioning challenges in the world by the Nuclear Decommissioning Authority (NDA). The project, located in one of Europe’s most demanding radiological environments, required innovative design solutions that allowed Enigma’s in-house design team to utilise state-of-the-art methods.

Project Summary

Initially constructed in the 1950s, the Pile Fuel Cladding Silo concrete ‘locked vault’ structure was purposely designed to safely store used cladding peeled away from the reactor fuel rods, alongside other radioactive materials from military projects and power plants, as well as other hazardous debris. The 60ft tall Pile Fuel Cladding Silo structure containing over 3,200 cubic metres of intermediate-level waste across six internal compartments stopped receiving waste in the early 1970s.

Enigma’s role was to support various temporary works requirements as the project team engineered solutions to access the top of the silo’s storage compartments, while maintaining an airtight seal to mitigate the threat of a spontaneous fire within. For the first-time in 65-years, the project team planned to access the storage compartments and retrieve the waste by utilising remote-operated robotics. Once the waste was safely retrieved, it was to be securely packaged in specially designed stainless-steel box containers and transported to the Box Encapsulation Plant Product Store for final disposal. In August 2023, the project team successfully retrieved the first waste from the Pile Fuel Cladding Silo using a crane to reach into the silo, lower a robotic arm into the compartment and lift out and repackage the waste. The boxes of waste are then transferred to the Box Encapsulation Plant Product Store – Direct Import Facility (BEPPS-DIF), which is a new above-ground storage facility that has been specially constructed on the Sellafield site. Enigma also played a pivotal role in the delivery of the BEPPS-DIF project (see separate case study online).

The first retrievals represent a significant milestone in the decommissioning story at Sellafield and a step closer to reducing the UK’s nuclear hazard.

Value Engineering

The PFCS project posed intricate challenges that demanded innovative solutions and Enigma’s internal teams worked diligently on-site at Sellafield and at the secondary Pile Fuel Cladding Silo site in Rosyth. Through early engagement with the various project stakeholders, Enigma’s involvement supported increased certainty of achieving the programme and project milestones and targets. One way in which this was achieved was by mobilising Enigma’s in-house Design Engineers, who worked meticulously to design temporary works around the Pile Fuel Cladding Silo mock-up and Pre-Assembled Units (PAUs) before they were transported to the Sellafield site. This strategic approach maximised efficiency during installation, demonstrating Enigma’s commitment to adopting alternate solutions to achieve operational excellence.